Electrical Safety Testing

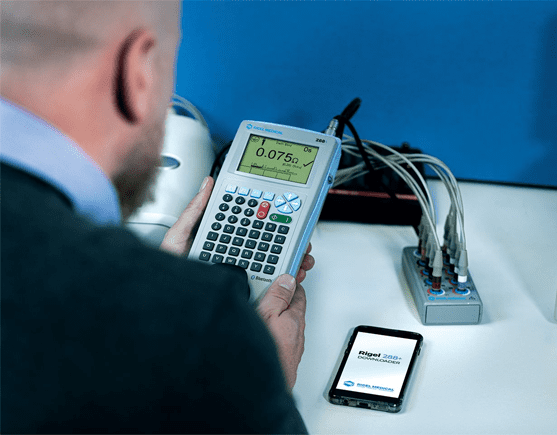

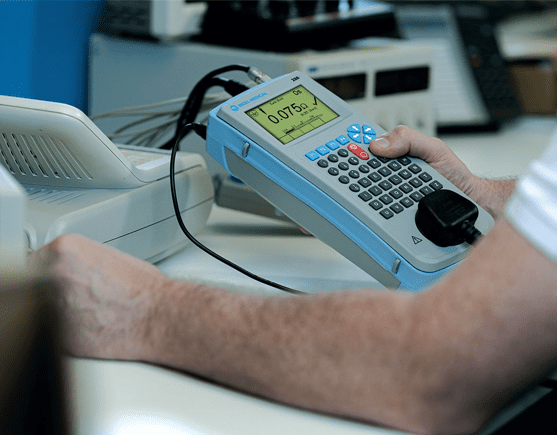

Ensuring patient and operator safety with our portable test solutions.

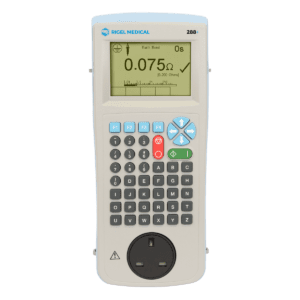

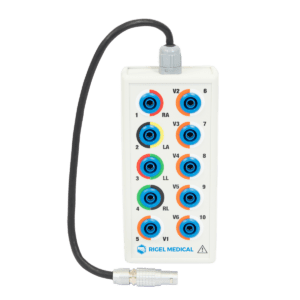

It is crucial that medical equipment is electrically safe for patients and users in a healthcare environment. Biomedical safety testing is paramount at Rigel. Our portable, lightweight electrical safety analysers are fast and accurate and conform to international and local safety standards.